Eccentric Wear Treatment Technologies

Source: Time:05-31-2012 Traffic: Read a total of3071Times

Our company is committed to eccentric wear detection and partial grinding to govern both the research, developed a set of ideal supporting technology:

1、Successful development of sucker rod axial force detector, the instrument can accurately detect the sucker rod in the production process by alternating load, and automatically record the sucker rod at different positions (including plunger pumps), stress condition, the formation of different depthsload curve of sucker rod and plunger load curve, calculation of the sucker rod and position, the plunger by the uplift forces on the sucker rod string required to increase the mound number of eccentric wear governance certain theoretical basis;

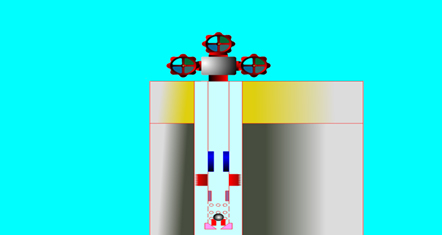

2、Environmentally friendly pipeline stretching to the drain, to prevent the tubing broken off well, lifting columns, automatic drain, pressure - two-way kava anchoring device, can effectively reduce the tubing bent to overcome tubing peristaltic reduce stroke loss to avoid pipelinethreaded wear;

Tubing stretch drain picture

Anchored to the drain

Pipeline stretching drain using the diagram

Tubing stretch drain device parameter table

| 技术参数Parameter |

LX–115 |

LX–150 |

|

适用套管外径(mm) |

139.7 |

177.8 |

|

最大外径 (mm) |

115 |

150 |

|

内通径 (mm) |

60 |

62 |

|

锚定压差 (MPa) |

8-12 |

8-12 |

|

轴向承载能力 (kN) |

≥200 |

≥200 |

|

释放负荷 (kN) |

80-120 |

80-120 |

|

泄油能力 (L/min) |

60 |

70 |

|

连接螺纹 |

27/8TBG |

27/8TBG |

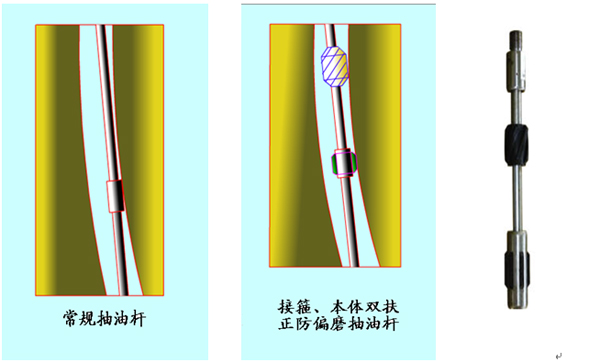

3、The development of anti-wear partial righting coupling, anti-high-intensity eccentric wear of sucker rods, can effectively reduce the inclined and henchman segment of the rod and tubing in direct frictional contact;

4、Sucker rods increase the mound

Righting function of the sucker rod to increase the ram, can effectively offset the sucker rod in the downstream process by resistance, to avoid the instability of the lower part of sucker rod bent helix, resulting in the rod and tubing wear;

Increase the ram parameters table

序号S/N

|

外 径(mm) |

长 度(m) |

重 量(Kg) |

|

1 |

46 |

0.75 |

7.88 |

|

2 |

46 |

1 |

10.5 |

5、Not reduce the yield of the premise, reasonable adjustments apheresis parameters to extend the cycle of production purposes.

Through the above measures, to achieve the following objectives:

①、Effectively overcome the peristaltic tubing, mining pump efficiency, avoid threaded wear, extend tubing scrap cycle;

②、Offset the plunger down resistance;

③、Avoid rigid contact of the inclined and henchman segment of rod and tubing, metal and non-metallic sliding friction, shear failure becomes extension tubing, sucker rod service life;

④、Reduce the sucker rod bending;

⑤、Reduce stroke damage, improve system efficiency of the pump;

⑥、Extend the cycle, reducing cost and increasing。